Careful Before Buying an Acrylic Bending Machine in Bulk

- aokaicnc

- May 7, 2025

- 4 min read

When you're planning to buy acrylic bending machines in bulk, it's not just about the price tag. Whether you're a manufacturer, wholesaler, or running a signage or fabrication business, making a smart bulk purchase requires insight, planning, and confidence in what you’re investing in. In this guide, we’ll walk you through everything you need to know before buying acrylic bending machines in wholesale quantities, from understanding the technology, key features to look for, common mistakes to avoid, to how to choose the best acrylic bending machine supplier.

What Is an Acrylic Bending Machine?

An acrylic bending machine is a specialized tool for heating and shaping acrylic sheets into desired forms. These machines apply heat evenly along a line, allowing the material to bend without cracking or losing clarity. They're widely used in signage, lighting fixtures, display stands, and furniture production.

Why Buy in Bulk?

If you're scaling up production or supplying machines to different branches or customers, buying in bulk has its perks: lower per-unit cost, streamlined logistics, consistent quality across batches, and room for customization or branding. But before you go all-in, it's crucial to understand what you're actually getting for your money.

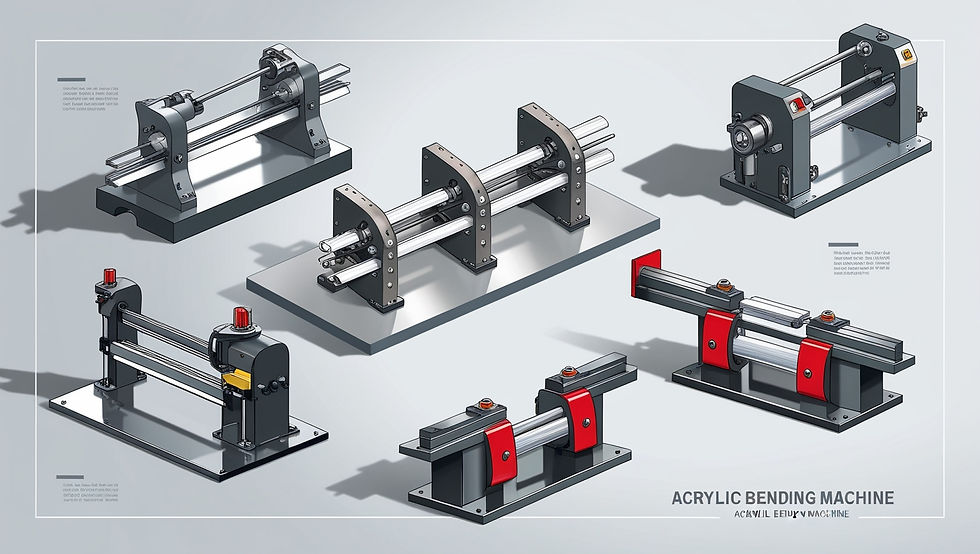

Understand the Different Types of Acrylic Bending Machines

Not all machines are created equal. Here's a quick breakdown of the main types:

Manual Acrylic Benders: Cost-effective and simple, great for smaller shops or low-volume work.

Semi-Automatic Bending Machines: Offer a mix of precision and affordability.

Fully Automatic Acrylic Benders: Best suited for large-scale operations with high throughput demands.

Multi-Line Benders: Allow for multiple bends simultaneously—ideal for complex shapes or mass production.

Knowing which type suits your business goals helps avoid over- or under-spending.

Key Features to Look for in a Quality Machine and Supplier

When browsing through bulk options, make sure to check these essential features: precise temperature control (crucial for clean, crack-free bends), adjustable heating elements (lets you work with various thicknesses and materials), fast heating time (improves productivity), durable construction (look for aluminum alloy or stainless steel frames), and a user-friendly interface (saves training time and reduces human error).

Material Compatibility Matters

Even though it’s called an “acrylic” bending machine, you might want one that can handle polycarbonate, PVC, PETG, and other thermoplastics. Multi-material compatibility adds versatility and expands your production capabilities.

Voltage and Power Requirements

Before importing or ordering in bulk, double-check the machine's voltage specifications. Machines built for one region’s electrical standards might not be compatible elsewhere. Ensure your factory or client base can operate the units without costly adaptors or converters.

Consider After-Sales Support and Warranty

This is one of a bulk purchase's most overlooked yet critical parts. Look for suppliers with clear warranty terms, readily available spare parts, technical support, and training or instructional materials. Trustworthy support means less downtime and better ROI in the long run.

Customization Options for Bulk Orders

Many manufacturers offer custom branding, specific machine sizes, or feature add-ons when you order in bulk. Ask the supplier about customization options like your brand logo on the machine, specific control systems or software compatibility, and modifications to bending width or angle settings. These tweaks could help your business stand out or better serve niche markets.

Freight, Shipping & Import Regulations

Ordering machines in bulk often means overseas freight. Ensure you confirm lead time, understand custom duties and taxes, ask if the supplier handles logistics or customs clearance, and review the packaging method (wooden crate, foam padding, etc.) to prevent shipping damage. Neglecting these details could lead to costly delays or losses.

Vet Your Wholesale Acrylic Bending Machine Supplier

Before placing a bulk order, check reviews and testimonials, request a product sample or live demo, ask about ISO certifications or CE compliance, review past projects or client case studies, and evaluate response time and communication quality. A reliable letter-bending machine supplier should be transparent, supportive, and open to collaboration. If they dodge questions or rush the deal, that’s a red flag.

Common Mistakes to Avoid

Even seasoned buyers can slip up. Here are some pitfalls to avoid: buying based on price alone instead of long-term value, skipping sample testing before the full order, ignoring technical compatibility, forgetting to plan for maintenance or spare parts, and trusting a supplier without doing thorough research.

Plan for Growth

Ask yourself: Will this machine still serve your business a year or two down the line? Scalable equipment might cost more upfront, but it could save you from needing to reinvest again soon. Option for machines that can evolve with your workflow, whether through software updates or interchangeable components.

Conclusion:

Buying wholesale acrylic bending machine in bulk is a big decision, but it doesn’t have to be risky. The key is to educate yourself, ask the right questions, and work with suppliers who genuinely care about your success. Take the time to understand your business needs, evaluate machine features, and invest in a solution that will pay off long-term. When done right, a bulk purchase boosts productivity and puts you ahead of the competition. Ready to make a move? Research, ask for support, and choose a partner, not just a product.

Comments